Technical information about the various types of Folberth motors, made by Trico:

FP/FPS: Older style, 1.5" bore, leather seals. Used in many trucks from the early 1940's through the late 50's, mainly military. Usually do not have a park feature, relying on operator to manually park the wiper with the handle.

FPD/FPDP/FPHP: Newer style, 1.5" bore, rubber/neoprene seals. FPDP style shown, with locking park mechanism. Used from the mid 1950's all the way through the 80's. Marine wiper motors are usually this type, mainly installed in Chris-Crafts with diesel engines. May or may not include a park feature. These motors may be installed as replacements for the above FP and FPS style motors, but use a different shaft.

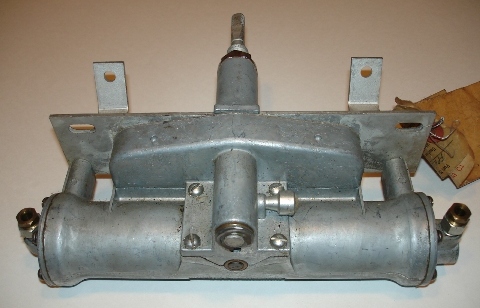

FDC: These motors are much larger than the standard Folberth, used in heavy-duty applications where very long wiper arms and blades are used. The shaft is gear driven using a very large metal gear, or in some cases, an internal cable and pulley system. The picture below shows a typical FDC style motor. These motors use a four port air control/valve in the dash, and the routing is more complicated than other systems.

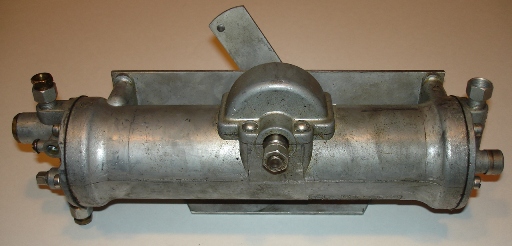

FSC, FSV: These have a round control valve on the inboard end of the shaft. Used for the same type of applications as the FDC style. An example from a Mack is below. Notice the tell-tale round valve in the center of the motor, and the exhaust outlet above the control valve in the center.

FPK: This style of motor is another variant of the heavy-duty big-bore Folberth wiper motors, and has an overly complicated internal design.

APM and APMH style: Not strictly "Folberth", made by Trico. Air-pressure, integrated speed control, auto-park. Mid 50's through the 60's. Used in applications where vacuum wiper motors were installed but engine options did not include a vacuum source, and there was no room for the larger Folberth style motor.

Click here to go to my Ebay store which includes many Folberth motors.